The brushless DC motor is composed of a motor body and a driver, and is a typical mechatronic product. Because the brushless DC motor runs in a self-control mode, it will not add a start winding to the rotor like a synchronous motor that is started under heavy load under variable frequency speed regulation, nor will it cause oscillation and out-of-step when the load changes suddenly. The permanent magnets of small and medium capacity brushless DC motors are now mostly made of rare earth neodymium iron boron (Nd-Fe-B) materials with high magnetic energy levels. Therefore, the volume of the rare earth permanent magnet brushless motor is one size smaller than the three-phase asynchronous motor of the same capacity.

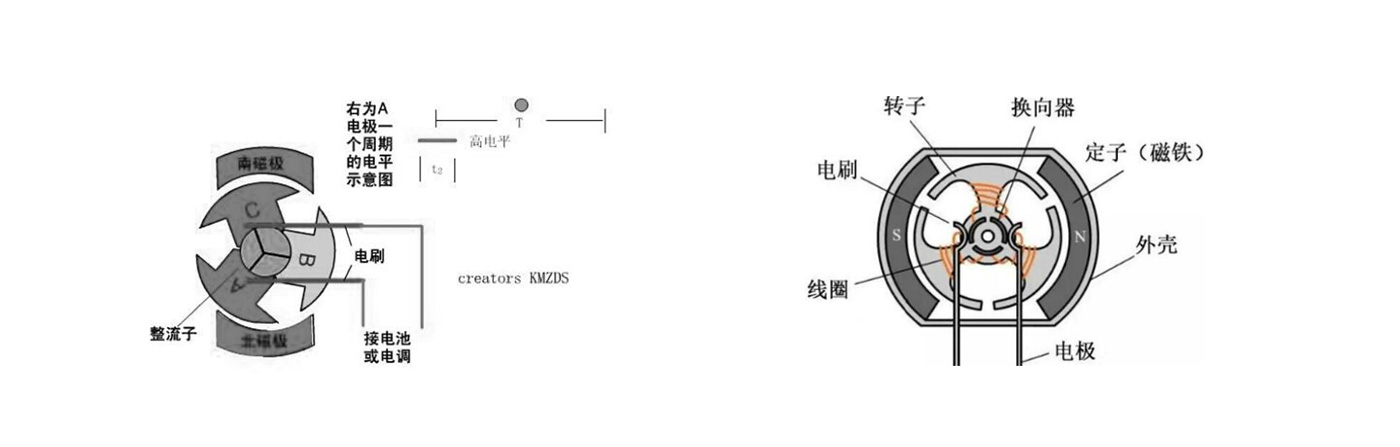

The brush motor adopts mechanical commutation, the magnetic pole does not move, and the coil rotates. When the motor is working, the coil and commutator rotate, but the magnetic steel and carbon brushes do not rotate. The alternating current direction of the coil is changed by the commutator and brushes that rotate with the motor.

The brush motor adopts mechanical commutation, the magnetic pole does not move, and the coil rotates. When the motor is working, the coil and commutator rotate, but the magnetic steel and carbon brushes do not rotate. The alternating current direction of the coil is changed by the commutator and brushes that rotate with the motor.

As the motor rotates, different coils or different two poles of the same coil are energized at different times, so that the NS pole of the coil generating magnetic field and the NS pole of the closest permanent magnet stator have a suitable angle difference. Repel each other, generate power, and push the motor to rotate. The carbon electrode slides on the coil terminal, like a brush on the surface of an object, so it is called a carbon "brush". Sliding with each other will rub the carbon brushes and cause wear and tear. The carbon brushes need to be replaced regularly; the alternating on and off between the carbon brushes and the coil terminals will cause electric sparks, electromagnetic breakage, and interference with electronic equipment.

In the brushless motor, the commutation work is done by the control circuit in the controller (usually Hall sensor + controller, more advanced technology is magnetic encoder). The brushless motor adopts electronic commutation, the coil does not move, and the magnetic pole rotates. The brushless motor uses a set of electronic equipment to sense the position of the magnetic pole of the permanent magnet through the Hall element. According to this perception, the electronic circuit is used to switch the direction of the current in the coil at the right time to ensure that the magnetic force in the correct direction is generated to drive the motor. . Eliminate the shortcomings of brushed motors.

So why do you need a special ESC on a quadcopter, and what is special about it? The quadcopter has four propellers, which are arranged in a crisscross structure. The rotation of the propeller is divided into forward and reverse rotation, which can offset the spin problem caused by the rotation of a single blade. The diameter of each paddle is small, and the centrifugal force when the four paddles rotate is dispersed. Unlike the propeller of a straight machine, there is only one inertial centrifugal force that can generate a concentrated centrifugal force to form a gyro, which prevents the fuselage from turning over quickly. So the usually used servo control signal update frequency is very low.

In order for the four-axis to react quickly to cope with the drift caused by the attitude change, a high-speed ESC is required. The update speed of the conventional PPM ESC is only about 50Hz, which cannot meet the speed required for such control, and the PPM ESC has a built-in MCU. PID steady-speed control can provide smooth speed change characteristics for conventional airplane models. It is not appropriate to use it on the four-axis. The four-axis needs a fast-reacting motor speed change. Using high-speed dedicated ESCs and IIC bus interface to transmit control signals, it can achieve hundreds of thousands of motor speed changes per second, and the attitude can be kept stable at all times during four-axis flight. Even if it was suddenly impacted by external forces, it was still safe and sound.