Electronic Technology Forum

Detailed explanation of PMOS process conditions and steps, advantages and disadvantages

MOS conventional process

In the development process of MOS circuits, the earliest and fastest development is PMOS integrated circuits. The production of PMOS circuits is basically a silicon planar process, which is usually called MOS conventional process. It has the advantages of simple process, uncomplicated equipment and easy control. However, PMOS circuits have the outstanding shortcoming of too low speed, which brings great difficulties to the development of high-speed, high-performance MOS large-scale integrated circuits. PMOS process. In order to improve circuit speed and performance, scientists have carried out a series of innovations to MOS technology. Some new materials and processes are used. For example, using semiconductor materials with high mobility, NMOS and GaAsNOS integrated circuits have been developed; in order to reduce the gate-source and gate-drain capacitances, gate self-aligned MOS technology has been developed; in terms of insulated gate dielectrics, compared to SiO span>2, better performance Si 3N4, Al 2O3, and other insulating films; in addition to the well-known aluminum gate, the gate electrode of the device has developed a thick silicon and aluminum gate; Ion implantation technology is used to form and adjust the threshold voltage, positive and negative of the device. PMOS process. In this way, the MOS integrated circuit process greatly exceeds the scope of the silicon planar process, showing the new characteristics of the MOS process. This chapter mainly introduces PNOS conventional process and new technology.

First, PMOS process

Although PMOS integrated circuits have a low operating speed, they have long been familiar to everyone. They are widely used, and combined with the advantages of simple technology and easy control, they are still mass-produced. The following briefly introduces its process principle and method.

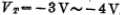

PMOS process conditions can generally be based on the threshold voltage VT Requirements to determine. The threshold voltage of common P-channel MOS devices is  . If you take an N-type silicon wafer with a doping concentration of

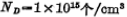

. If you take an N-type silicon wafer with a doping concentration of  , both have an oxide layer Thickness

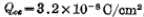

, both have an oxide layer Thickness  , then

, then  . PMOS process. In order to obtain a smaller surface state density, take the single crystal silicon in the direction of<100>, if the effective positive charge density is controlled at 2×1011/cm3 the number of Contains

. PMOS process. In order to obtain a smaller surface state density, take the single crystal silicon in the direction of<100>, if the effective positive charge density is controlled at 2×1011/cm3 the number of Contains  . Substitute these numbers into the expression VT Get:

. Substitute these numbers into the expression VT Get:

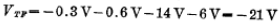

If the thick oxide layer is 1.5μm, the field threshold voltage can be estimated as:

< /span>

< /span>

In the actual process, due to the contamination of the oxide layer by impurity ions (especially sodium ions), the effective positive charge density in the oxide layer will be greater than 2×1011pcs/cm2 the number of lVTl is bigger. Therefore, it is particularly important to prevent contamination by impurities in each link of the MOS process.

1. PMOS process conditions and steps

(1) Once oxidation

The N-Si single wafer with a resistivity of 8Ω.cm and a thickness of about 800μm is strictly cleaned, and a layer of about 1~ is grown on the surface of the Si wafer by thermal growth method. 1.5μm SiO2 film, as a diffusion mask and surface protection layer. The process conditions are:

, Oxidation time

, Oxidation time  , oxygen flow rate is

, oxygen flow rate is  , the temperature of wet oxygen water is 98℃.

, the temperature of wet oxygen water is 98℃.

(2) Boron diffusion manufacturing drain-source area

For Si wafers with pre-engraved source and drain windows, perform high boron pre-diffusion first, and then perform re-diffusion to form P regions (source and drain regions).

The conditions for the diffusion of boron are: Nitrogen flow rate N2(large)=600ml/min, N2(small, Tongyuan)=10ml/min, time t=5( No source), 30' (Tong source), 5'(Go to source), liquid source (trimethyl borate) temperature is 0℃, requirements

Nitrogen flow rate N2(large)=600ml/min, N2(small, Tongyuan)=10ml/min, time t=5( No source), 30' (Tong source), 5'(Go to source), liquid source (trimethyl borate) temperature is 0℃, requirements  □.

□.

The conditions for spreading are:  ; time t=5'(dry)+25(wet)+10'(dry); water temperature Twater< /strong>=98℃; oxygen flow rate O2=800ml/min. Requires R□=40~60Ω/□.

; time t=5'(dry)+25(wet)+10'(dry); water temperature Twater< /strong>=98℃; oxygen flow rate O2=800ml/min. Requires R□=40~60Ω/□.

(3) Gate oxidation process

The original oxide film in the gate area is carved away, and a high-quality thin silicon dioxide layer is regrown as the insulating medium of the gate. From the previous discussion, we know that the SiO2 under the gate has a great influence on the performance of the device. PMOS process. MOS device threshold voltage VT, and SiO2 Layer thickness and its equivalent positive charge density

and its equivalent positive charge density Yes Great relationship. To control VT must be strictly controlled

Yes Great relationship. To control VT must be strictly controlled ,

,  . The process conditions are:

. The process conditions are:  oxygen flow

oxygen flow ; oxidation water temperature=98℃; oxidation time

; oxidation water temperature=98℃; oxidation time (dry)+22'(moisture)+5< span style="font-size: 18px;">'(dry), and denitrogenate 10'.

(dry)+22'(moisture)+5< span style="font-size: 18px;">'(dry), and denitrogenate 10'.

(4) Phosphorus treatment process

Place the gate-oxidized wafer in a high-temperature furnace to decompose the phosphorus atoms on the silicon surface and grow a layer of phosphosilicate glass, which will passivate the surface and reduce the contamination of Na+ The influence caused by the device makes the device performance stable. Phosphorus treatment process conditions are:  , open source, oxygen flow

, open source, oxygen flow  , large nitrogen (N2)=320ml/min, the source (phosphorus oxynitride) temperature is 0℃. Requires

, large nitrogen (N2)=320ml/min, the source (phosphorus oxynitride) temperature is 0℃. Requires  .

.

(5) Nitrogen blowing (nitrogen baking) process strong>

Put the phosphor-treated film into a furnace at a high temperature of 950C through nitrogen for 30',N2The flow rate is 200ml/min, which expands the phosphorus atoms on the surface to the depth. It can more effectively control Na+, and at the same time reduce the concentration of surface phosphorus, which is convenient for photolithography.

The process flow is shown in Figure 6-1. PMOS process.

2. Disadvantages of PMOS

PMOS integrated circuits produced by conventional processes have some weaknesses, which affect the further improvement of circuit performance.

First, the circuit produced by the typical PMOS process has a relatively high threshold voltage of the tube, the absolute value is generally around 3.5V, so a higher working power supply (about -20V ), in this way, it is not compatible with bipolar circuits that use a low power supply (about 5V).

Second, the speed/power consumption of PMOS circuits is at least one amount lower than that of bipolar circuits class. Although the power consumption of MOS circuits is lower than that of bipolar circuits, the speed of bipolar circuits is much faster than that of PMOS circuits.

To improve the performance of the circuit, on the one hand, we must reform the original technology, on the other hand, we must develop a new type of MOS circuit.

Contact: Mr. Zou

Tel: 0755-83888366-8022

Mobile: 18123972950

QQ: 2880195519

Address: 5C1, CD Block, Tianji Building, Tian’an Digital City, Chegongmiao, Futian District, Shenzhen

Please search WeChat Official Account: "KIA Semiconductor" or scan the following picture to "Follow" Official WeChat Official Account

Please "Follow" the official WeChat account: provide MOS tube technical assistance